Production technologies of corrugated board packaging

We produce packaging from single, double and triple wall corrugated board in various flute combinations: E, B, C, BC, EB, CC, EE, BCB, AAC. Operating with various technologies allows us to produce a wide range of packaging:

We produce packaging from single, double and triple wall corrugated board in various flute combinations: E, B, C, BC, EB, CC, EE, BCB, AAC. Operating with various technologies allows us to produce a wide range of packaging:

- slotted boxes (regular, overlap, auto-lock bottom, telescoping, folders, wraparound)

- die-cut boxes

- heavy duty packaging

- ready-glued boxes - 3, 4, 6 points of gluing

- e-commerce packaging with self-adhesive closures and tear-off strips

- accessory elements inside boxes: standard inserts, reinforcing inserts, dividers

- Slotted boxes – simple type of packaging not requiring additional production tools; the packaging leaves the machine already in a ready-to-use form. Those boxes do not require folding or additional gluing apart from one glue flap.

- Rotary die-cut boxes – often large-size or high volume packaging. Boxes of any shape can be produced using this method, both, those listed in the FEFCO's catalogue and constructions designed individually.

- Flat-bed die-cut boxes - provide the possibility of producing a similar range of packaging designs as rotary die-cutting, but with significantly greater precision. Here, we can design folding or opening creasing lines and cuttings with millimetre accuracy.

Printing techniques

Flexographic printing is made by stamping a flexible, digitally prepared polymer die directly on corrugated board, cardboard or paper. This method has many advantages. Good price-quality ratio. It allows printing directly on press-elastic materials - such as corrugated board. Inks for flexographic printing may contain enriching additives: anti-abrasive, fast drying, brightening colours. They are strictly controlled for the content of potentially hazardous substances. You can also use unique water-based biodegradable inks based on renewable raw materials.

Flexographic printing is made by stamping a flexible, digitally prepared polymer die directly on corrugated board, cardboard or paper. This method has many advantages. Good price-quality ratio. It allows printing directly on press-elastic materials - such as corrugated board. Inks for flexographic printing may contain enriching additives: anti-abrasive, fast drying, brightening colours. They are strictly controlled for the content of potentially hazardous substances. You can also use unique water-based biodegradable inks based on renewable raw materials.The same printing technology allows to cover the surface with special coatings - VCI, barrier coatings, varnishes. It is also possible to print on both sides of the corrugated board at the same time.

Offset printing is used where the graphic motifs on the packaging should be more impressive. This is an indirect printing method in which metal plates carrying the ink are pressed against blanket-lined cylinders and they in turn transfer the ink onto paper. The undoubted advantage of this printing method is its speed and high quality. It becomes cost/price advantageous with larger volumes, which spread out the higher cost of machine set-up onto a bigger number of pieces produced.

Offset printing is used where the graphic motifs on the packaging should be more impressive. This is an indirect printing method in which metal plates carrying the ink are pressed against blanket-lined cylinders and they in turn transfer the ink onto paper. The undoubted advantage of this printing method is its speed and high quality. It becomes cost/price advantageous with larger volumes, which spread out the higher cost of machine set-up onto a bigger number of pieces produced.Offset printing is usually finished with dispersion varnish. Selective varnish, UV varnish or hybrid varnish can also be used. Offset inks themselves can also be enriched with additives that increase the marketing value of the packaging: additives of metallic pigments, pearly pigments, fluorescent pigments.

Types of corrugated board

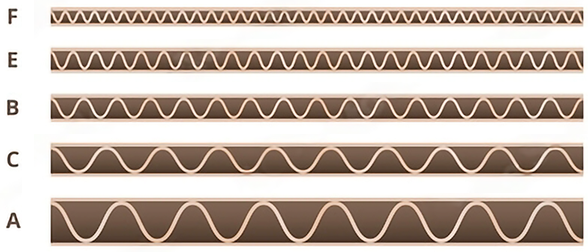

Corrugated board consist of flat (liners) and fluted (flutings) layers of paper glued alternately together. Flutings may have different heights. Due to this this height, the whole sheet of corrugated board will vary in thickness. And this thickness, in turn, divides corrugated board types (single wall – two liners and one fluting):

Corrugated board consist of flat (liners) and fluted (flutings) layers of paper glued alternately together. Flutings may have different heights. Due to this this height, the whole sheet of corrugated board will vary in thickness. And this thickness, in turn, divides corrugated board types (single wall – two liners and one fluting):

- flute F – thickness 0,7 – 0,8 mm

- flute E – thickness 1,1 – 1,7 mm

- flute B – thickness 2,5 – 3 mm

- flute C – thickness 3,4 – 4 mm

- flute A – thickness 4,1 – 4,7 mm

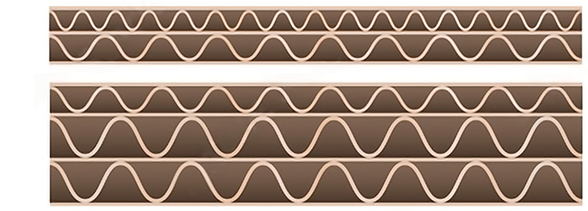

By using combinations of these flutes, we can have corrugated board with more layers:

By using combinations of these flutes, we can have corrugated board with more layers:

- 5-layer cardboard (doble wall) – the most popular combinations: EB, BC, EC

- 7-layer cardboard (triple wall) – the most popular combinations: BCB, AAC

Production technologies of paper bags

Paper bags complement our range of products addressed mainly to the food, chemical and construction industries. We focus on two types of bags:- Open mouth glued bags – meant for packing food products (frozen foods, concentrates, flour, salt, rice), chemical products (granulates, PVC) or construction products (plasters, adhesives).

- Valve bags – meant for packing food products (animal feed, flour, powdered milk), chemical and construction products (cement, plaster, sand) to be filled automatically.

Unison Opakowania Sp. z o.o.

Bydlino, ul. Leśna 10

76-200 Słupsk, Poland

+48 791 233 205

office@unison-opakowania.pl

Bydlino, ul. Leśna 10

76-200 Słupsk, Poland

+48 791 233 205

office@unison-opakowania.pl

Go to page: